In the current mining and mineral processing practice, rock crushers are a key feature. They are employed to shred large blocks of ore into small, manageable portions that can be refined. The effectiveness of this process will impact material processing, energy use, and throughput. Companies today seek sophisticated solutions to meet the increasing demands for productivity. Efficiency and durability are still primary considerations when shopping for a rock crusher for sale. Eastman offers proven equipment that meets those standards in both large and mobile applications.

Essential Role of Rock Crushers in Mining Operations

The first process of mineral processing is ore reduction. Ore blocks of large size cannot be processed directly in grinding mills. The large rock is broken down to an acceptable size for grinding and concentration using a rock crusher. The process enhances throughput and improves the separation of valuable minerals. Without effective crushing, subsequent operations, such as grinding and flotation, will be affected. Crushing is the basis of the productivity of the whole mineral extraction chain.

Static Rock Crushers for Heavy Duty Applications

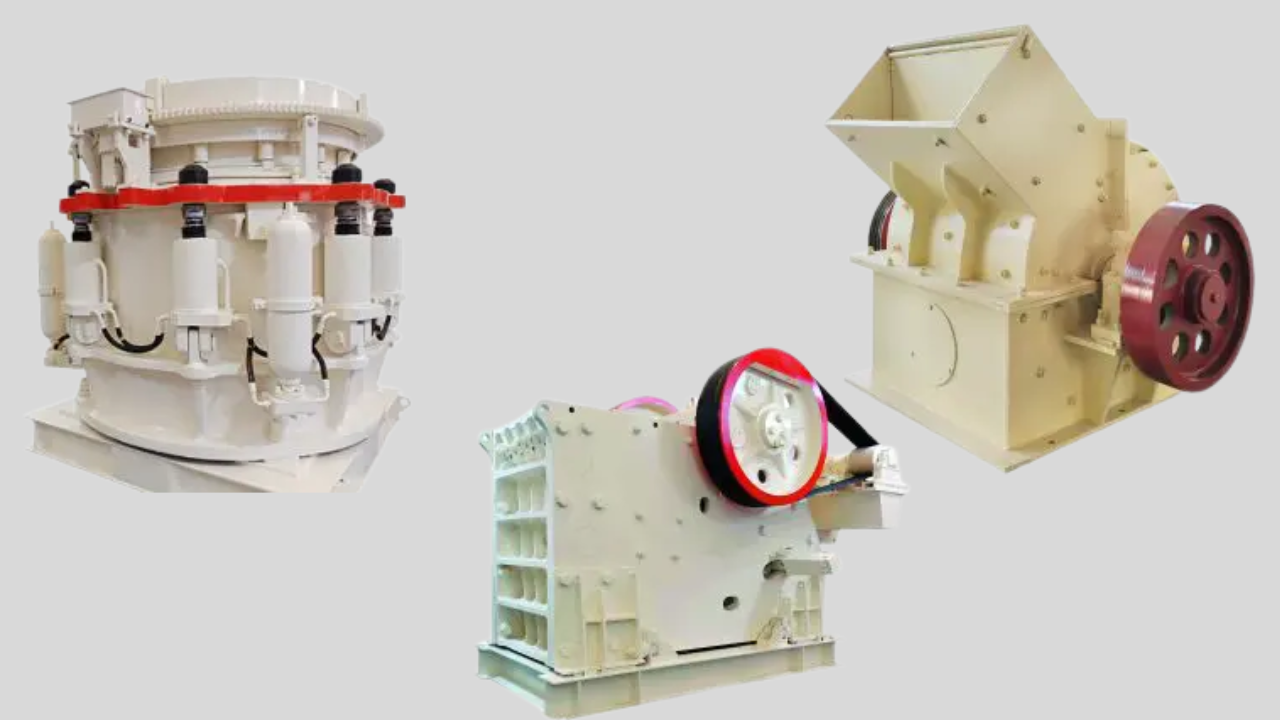

Stationary crushers are still best suited for fixed mining locations with a steady demand for materials. These are jaw crushers, impact crushers, hammer crushers, roller crushers, and cone crushers. Each design is specifically used for a particular crushing application. Jaw crushers are suitable for large feed sizes, up to 1200mm, and output sizes ranging from 10mm to 350mm. An impact crusher is a type of crushing equipment that processes medium-hardness materials, characterized by a large crushing ratio. Hammer crushers have fine output sizes as low as 0-15mm, making them suitable for softer ores. Cone crushers, including single-cylinder and multi-cylinder cones and Symons cones, can crush hard stones such as granite and basalt with a throughput of up to 1200t/h. Static systems are well-suited for mines where continuous production is essential.

Mobile Rock Crushers: Versatility for Modern Mines

Mobility is helpful for many mining operations because the locations are constantly changing. The mobile rock crushers enable work to be transported directly to the ore field. Types of mobile jaw crusher, mobile impact crusher, mobile cone crusher, and mobile sand making machine. They eliminate the need for intensive hauling, saving costs and time in operations. Mobile units also reduce the time-to-production cycle by processing materials at the point of use. Their applications are particularly suitable for fieldwork, building sites, and recycling operations. This mobility offers rapid set-up, flexibility, and competent material management.

Matching the Type of Crusher To The Mineral Properties

Material hardness, abrasiveness, and moisture content guide the selection of a crusher. Stone materials, such as granite, quartz, and basalt, require jaw or cone crushers that are durable in terms of wear. Impact or hammer crushers can be utilized on softer minerals, such as limestone or barite. Moisture also influences performance in the sense that sticky material is clogging some machines. The specific match of the mineral with the correct crusher will save energy and, consequently, reduce wear expenditures. By selecting the appropriate equipment, processing will be made very smooth, efficient, and cost-effective.

Crushing Performance Metrics that Define Efficiency

Crusher efficiency is dependent on several quantifiable variables. Throughput capacity refers to the amount of material processed per unit of time. Operating costs will depend on power consumption. An optimum balance provides maximum tons per kWh. Product size distribution is another crucial parameter. Smaller and uniform particles enhance grinding efficiency and mineral separation. Durability also matters. Strong construction and longer maintenance intervals minimize downtime. These parameters facilitate informed decisions when selecting crushing equipment for mining projects.

Creativity and Durability in Eastman's Rock Crushers

Eastman focuses on developing solutions that are safety-centered, efficiency-centered, and reliability-centered. The design of every machine is upgraded. Saving energy and extending service life are the basis of innovations. The mining, smelting, and aggregate production industries worldwide utilize Eastman crushers. It is a company that has been operational since 1985. It has grown to be an accredited distributor of cost-effective crushing and screening gear, which it has earned through the merit of its products, wit, and outstanding service. Through the provision of long-life machines, Eastman serves industries that require machines that can withstand harsh environments.

Conclusion

Rock crushers cannot be replaced in the mining and mineral processing industries. They precondition effective grinding, concentration, and separation. The project size, site conditions, and mobility requirements determine the selection of stationary and mobile crushers. The optimal choice of a match between material and crusher type guarantees real efficiency and cost control in the long run. Performance metrics, including throughput, energy use, and durability, can measure operational success. The introduction of crushers into complete processing facilities increases resource utilization and productivity in the project. Eastman continues to trend in this direction with trusted designs, new features, and a focus on ensuring efficiency in all its uses.